Shipbuilding has been a significant industrial activity in Tasmania since the early colonial period. It flourished through the need for vessels to carry the greater part of commerce around the Tasmanian coast, interstate and overseas. Most of the vessels have been built between Hobart and the Huon valley in southern Tasmania, due to the availability of timber in the southern forests and the sheltered waterways.

“The British were not only attracted to Van Diemen’s Land because of its suitability as an island penal colony fortress, but, because it had an abundance of timbers such as the famous Huon, King Billy and celery top pines,” says Paul Cullen, the long-time director of Hobart’s biennial Wooden Boat Festival.

As Paul explains, the UK had a shortage of suitable boat building timber and the Huon had an abundance, locked up for thousands of years. So it made sense to send a few thousand convicts there to help the logging.

Port Arthur – a place of industry and redemption

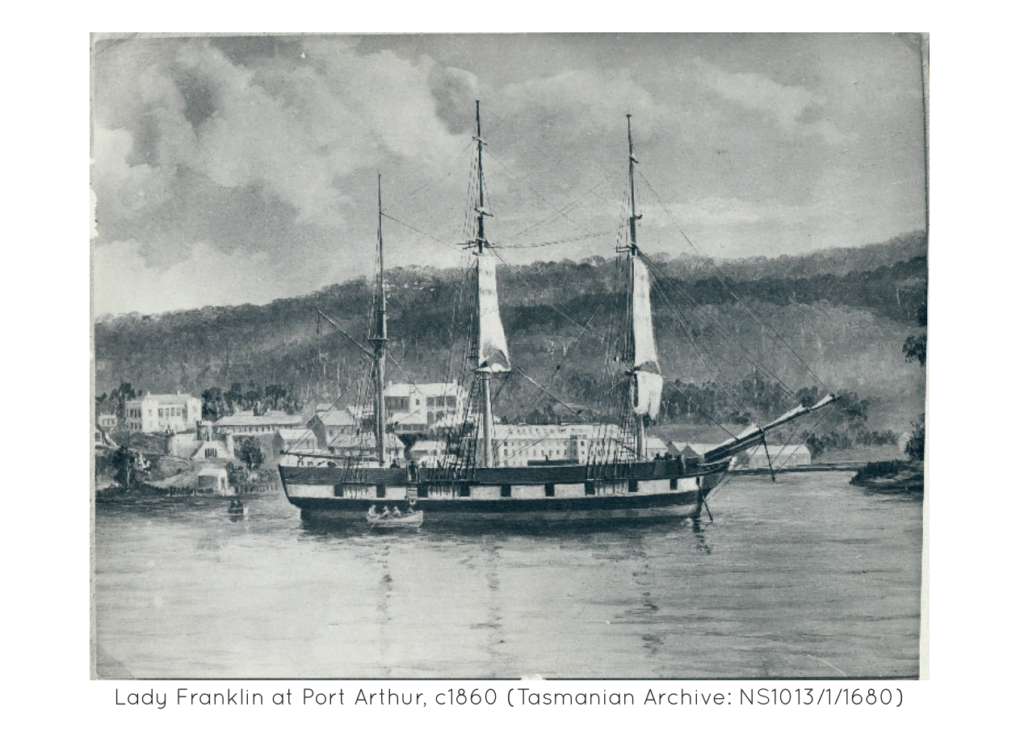

The dockyard at the Port Arthur penal colony operated from 1834 to 1848. In just 14 years, 16 large decked vessels and around 150 small open boats were built here, and a large number of repairs were performed. Many of the boats were eight-oared whaleboats that were used by whalers and for general transport. A testimony to the quality of ships built here was the Lady Franklin – built in 1842, the ship saw use as a transport ship for prisoners and soldiers, and then as a whaling ship. At its peak, the dockyard employed up to 70 men. Skilled men were always in short supply so many convicts were trained in the boatbuilding trade.

Waterways – the highways of the day

The town of Franklin was named after Sir John Franklin and his wife Lady Jane Franklin, who in 1839 subdivided a large property in Franklin to settle families of modest means. The Franklins had a ketch named Huon Pine, built at Port Davey to provide a direct link between the settlement and Hobart. Before roads were built between the Huon valley and Hobart, river travel was the only method of reliable transport until the 1930s.

The first locally-built seagoing vessels were the 40-ton schooner Henrietta Packet and 133-ton brig Campbell Macquarie, in 1813. By the late 1820s shipbuilding was a significant industry. In the 1840s the industry experienced a boom. Richard Hill from Honeywood (now Geeveston), was the son of convict Barney Hill, transported in 1817. His water-powered sawmill just above the last rapid on the Kermandie River opened in the late 1840s and was the Huon’s first privately-owned sawmill. Hill supplied the local boatbuilders and also built the schooner Annie Hill and the ketch Governor Weld, both used in his timber trade. Timber pioneer Richard Hill laid the first tramways in the Huon, reaching up several kilometres into the forests to retrieve timber.

In 1871 moderately large seagoing sailing ships were built, the most famous being the locally owned barque Harriet McGregor for the Hobart–London trade.

The SV May Queen was built on the banks of the Huon River near Franklin. She is an excellent example of these sail trading ketches – shallow draft vessels, generally with a centreboard, that allowed them to enter river mouths to load and unload produce and timber. Her hull is made from Tasmanian blue gum and stringybark and her deck is celery top pine.

Most towns along the waterway route to Hobart had their own jetty. Some of these jetties had scalloping sheds, where five gallon tins of the delicious molluscs were filled and exported to the Hobart docks and Henry Jones’ IXL cannery to be exported globally. The SV May Queen had a working life of 106 years. She is now Australia’s oldest sail trader afloat. You can see this magnificent vessel moored today at Waterman’s Dock in Hobart.

Shipbuilding after the 1880s was limited to coastal and interstate sailing vessels, and small river and coastal steamers fitted with (mostly) imported engines.

A century and a half of experience and skill

Established in 1863, Wilson’s Boat Yard is one of Australia’s oldest continually-operating boatbuilding businesses. Founder John Wilson often went into the bush to select the right tree for his boats, and with only simple hand tools designed and built thirty large timber boats, mainly trading ketches for the brisk business of carrying cargo and passengers in Tasmanian waterways. He is remembered as one of the best boatbuilders ever to work in Tasmania.

The Wilson Brothers built the ketch Evaleeta, which was the flagship at the annual Royal Hobart Regatta. Highly skilled and experienced artisan craftsmen continue the tradition today, building and restoring timber boats at Abels Bay with a magnificent view over Port Cygnet. Finished boats slide straight out into the Cygnet River.

A Huon boatbuilding renaissance

Paul D’Olier, the manager of Australia’s only wooden boat school at Franklin, says interest in boatbuilding at the school is at a peak, with most classes booked out for the next few years. The school uses mostly Huon pine and celery top pine timbers. Most of the traditional clinker dinghies built by students are pre-ordered by a sponsor or student.

“We order suitable hand-picked salvaged logs with the least amount of imperfections and in longer lengths from a sawmill supplier,” Paul says. “Huon pine is scarce and expensive but its high oil content means it won’t rot. The boat-grade timber often has to be ordered six months in advance and arrives pre-cut and dried.”

The founder of The Wooden Boat Centre in Franklin, John Young, suggests that in an age of speed and cheap materials, wooden boatbuilding is an act of uncommon precision and reverence – a sanctuary for those ‘seeking slow’. Both Paul and John have seen a renaissance in boatbuilding in the Huon, with people moving to the region to complete a wooden boatbuilding course.

From the Huon to the high seas

Ten years ago Cygnet Wooden Boats was started by Jeremy Clowes , a qualified and very experienced boatbuilder. The sprawling shed, on the road just out of Cygnet on the way to Lymington, was a sawmill dating back to the 1880s – it still has the large 150 year old brick kiln which was used to create charcoal for medicinal purposes in the 1800s. They are currently recommissioning five boats. Jeremy says that one third of their business comes from the mainland. Cygnet Wooden Boats can be price competitive because the rental is much lower than a space on Sydney Harbour or Sorrento in Victoria for example. The Huon also has easy access to materials and skilled labour.

cygnetwoodenboats.blogspot.com

In a large old ex-packing case shed at Glen Huon with huge rusty-stained red corrugated iron doors lies a secret Huon jewel. A 40 foot pilot cutter weighing 16 tons, Tarkine is being built by adventurous young couple Matthew Morris and Lefke Van Gogh. They met on the well-known Dutch Tall Ship Bark Europa built-in 1911, which sails around the world and even to Antarctica.

With a dream to build their own boat, they started the design in late 2019. With a limited budget, most of the labour is done by them with the guidance of local boatbuilder Dave Golding, who owns the shed.

They recently reached a milestone with the completion of the planking. After 3000 bronze screws, 12kg of bronze nails, four drills (cheaper is not better they say), over 100 litres of epoxy resin, and more than 100 planks each side, the hull in Tasmanian hardwood is complete.

Matt, who grew up learning to sail on the Huon River, is an apprentice boatbuilder at Cygnet Wooden Boats and Lefke is a labourer there.

“We build as we earn and some months it’s a bit tight,” Lefke says.

Matt says many locals have donated items or materials for the boat. The couple ‘live boats’ seven days a week. They spend about four days a week on Tarkine and expect she may take four years to build.

Lefke is looking forward to finishing Tarkine with some special bronze fixtures they found in the Netherlands. They hope to have her in the water at the 2023 Wooden Boat Festival. Then, their patience and attention to detail will be rewarded.

“When the Tarkine is ready, we want to sail her across the world and show our new home to Lefke’s family in The Netherlands,” Matt says.

Their enthusiasm is infectious. Their Facebook site aboatbytheriver documents their incredible journey from a Huon packing shed to the high seas.